Pentaerythritol Stearate(PETS)

Pentaerythritol stearate acts as internal and external lubricants and release agents for Polycarbonate, alloy, nylon (PA66, PA6), ABS, polyphenylene oxide (PPO), polyphenylene sulfide (PPS); lubricants and dispersants for Thermoplastic polyester (PBT, PET); lubricants and dispersants for other engineering thermoplastic like PA, POM, PP, ABS, PVC, HIPS, PE ; antistatic agent, lubricant, dispersant, anti-fogging agent for polypropylene (PP) and polyethylene (PE); antistatic agent, anti-fogging agent for polystyrene (PS); antistatic agent, lubricant and anti-fogging agent for polyvinyl chloride (PVC); slip agent, anti-fogging agent for polyurethane (PU); lubricant for thermosetting plastics. (FDA approved, allowed for food packaging materials). PETS has good thermal stability and low volatility at high temperature; good mold release and flowing performance. Main application of PETS: high efficiency lubricants, PVC stabilizer, and raw material for plasticizer and rubber additives.

Product Details:

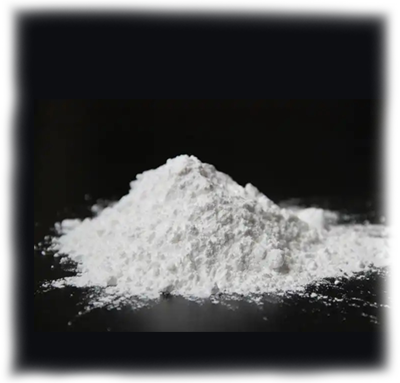

| ● Appearance:white solid wax flake、powder or beads | ● Place Orign: China | ||||

| ● Formula: | PETS-3 | PETS-4 | ● CAS No.: | PETS-3 | PETS-4 |

| C59H114O7 | C77H148O8 | 28188-24-1 | 115-83-3 | ||

| ● Shelf Life: 24 month | ● Certification: ISO9001 | ||||

Payment & Shiping Terms:

- Minimum Quantity: 1MT

- Packaging Details: 25kg/bag or 500kg/bulk bag,PE inner bag

- Delivery Time: 10-15 days

- Payment Term: T/T

- Appearancewhite solid wax flake、 powder or beads

Specifications:

| Items | PETS-3 | PETS-4 | High Grade PETS–4 |

| Acid Value(mgKOH/g) | 2.0 Max | 3.0 Max | 2.0 Max |

| Iodine Value (gI2∕100g) | 1.0 Max | 2.0 Max | 2.0 Max |

| Hydroxyl Value(mgKOH/g) | 55-65 | 25-35 | 12 Max |

| Melting Point(ºC) | 50-60 | 55-65 | 60-70 |

| CAS No. | 28188-24-1 | 115-83-3 | |

| Mol. Wt. | 934 | 1216 | |

| Molecular Formula | C59H114O7 | C77H148O8 | |

Package:N.W. in paper bag (25kgs) or Bulk bag (500kgs)

Storageand Shelf life : Stored in dry and cool places. 2 years

Application:

Characteristics:With good heat stability and low volatility under high temperature(TGA shown 400℃ for high grade type PETS-4).

1. PETS can be applied as one higher effective lubricant anddispersing agent in plastics and rubber industry.Compared with PE wax or EBS, PETS has the advantages of low addition amount, excellent high-temperature resistance, outstanding lubricity, and no impact on transparency. (PETS-3 is mainly used in the processing of PA6 and PA66 nylon materials as a high-temperature lubricant and anti-bond fiber exposure agent. PETS-4 can be used for PC, PC/ABS alloys, polyphenylene oxide (PPO), polyphenylene sulfide (PPS), thermoplastic polyesters (PBT, PET), PA, POM, PP, PE, and ABS as a high-temperature environmentally friendly external lubricant or internal demolding agent.) it will mix the main resin with the adding agent more uniformly without defect spot occurred,Besides this,it also show easierdemoulding of the made-up articles from the Molds and improve the plasticization,especially PETS-4 is the ideal choice of internal and external lubricant for transparent PC

Dosage: 0.1-1phr.

2. PETS can also be used as a balanced internal and external high-temperature environmentally friendly lubricant and auxiliary heat stabilizer for preparing powder environmental calcium-zinc composite heat stabilizer systems and powder rare earth composite heat stabilizer systems. Compared with other lubricants, it has better high-temperature lubrication performance and low volatility, and does not precipitate and does not affect the transparency of the original product. Due to the fact that this product is environmentally friendly, non-toxic and has excellent compatibility with PVC, it can also be directly used in PVC cable materials at 105°C or other heat-resistant levels as an efficient lubricant and auxiliary heat stabilizer. It does not precipitate and can significantly improve the extrusion speed of the cable material and the gloss of the processed product. PETS-3 focuses on internal sliding, and PETS-4 focuses on external sliding.

Dosage: 3-5phr(as 100PHR PVC).

3. Rubber industry applications,Pentaerythritol tetra stearate is one excellent rubber dispersant and lubricant,can effectively prevent the sticking of the compounds to the rubber rolls,and has positive effect regarding flow and demoulding properties with the injection and mould releasing process,most suitable for synthetic rubber,e.g. H-NBR,ECO/CO,FKM,EPDM,CSM,CR,SBR.

Dosage: 3-5 phr

4. Oilfield industry application,Pentaerythritol tetra stearate also acted as one excellent lubricant applied in the oilfield industry which is biodegradeable,several world famous oilfield service company are now sourcing this solid lubricant for their compounding of oilfield drilling fluids.

Note:

Pentaerythritol tetrastearate and Pentaerythritol tristearate series have gained REACH pre-registration number and passed SGS inspection concerning SVHC(138 items) and RoHS directives requested by REACH of EU.

..Get Every Answers..

Ask Question

.. contact us ..